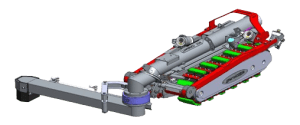

Our Robot Features

- Zone ‘0’ (Equivalent to Class 1 Div 1) Ex certified robotic equipment.

- Remotely operated from airconditioned control room.

- ADR spec Jet/Vac tipping tanker with 9000L capacity.

- 3,500 PSI Jetting / 240 bar jetting.

- Multiple tracks.

- External ramps fitted to 24”/600mm manway.

- Zone ‘0’ Camera and lighting system.

Washing Heads

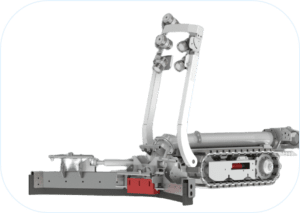

Auger Head

This allows us to breakdown and remove the heaviest of sludges.

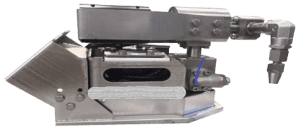

Squeegee Head

This is used for lighter sludges.

Adjustable Jetting Head

This is used to jet wash the tank when the majority of the sludges/scale have been removed.

360 Degree Washing Head

This allows us to clean internal tank furniture such as pipework, roof legs, underside of floating roof and shell walls up to 2m in height.

Low Profile Head

This allows us to clean underneath pipework and under heating coils.

Engineering

Engineering Solutions for Better Working Environments

At Re-Gen, our dedicated team of in-house engineers is committed to advancing our products through continuous research and development. We understand that every client location presents unique challenges, and we strive to create customised solutions to meet these needs.

Our state-of-the-art engineering and R&D facilities enable us to:

Enhance Performance

Implement modifications to boost efficiency and effectiveness.

Maintain High Standards

Ensure our equipment is always operating at peak performance.

Innovate for Better Workplaces

Engineer solutions that improve working environments.