Revolutionising safety in oil tank cleaning

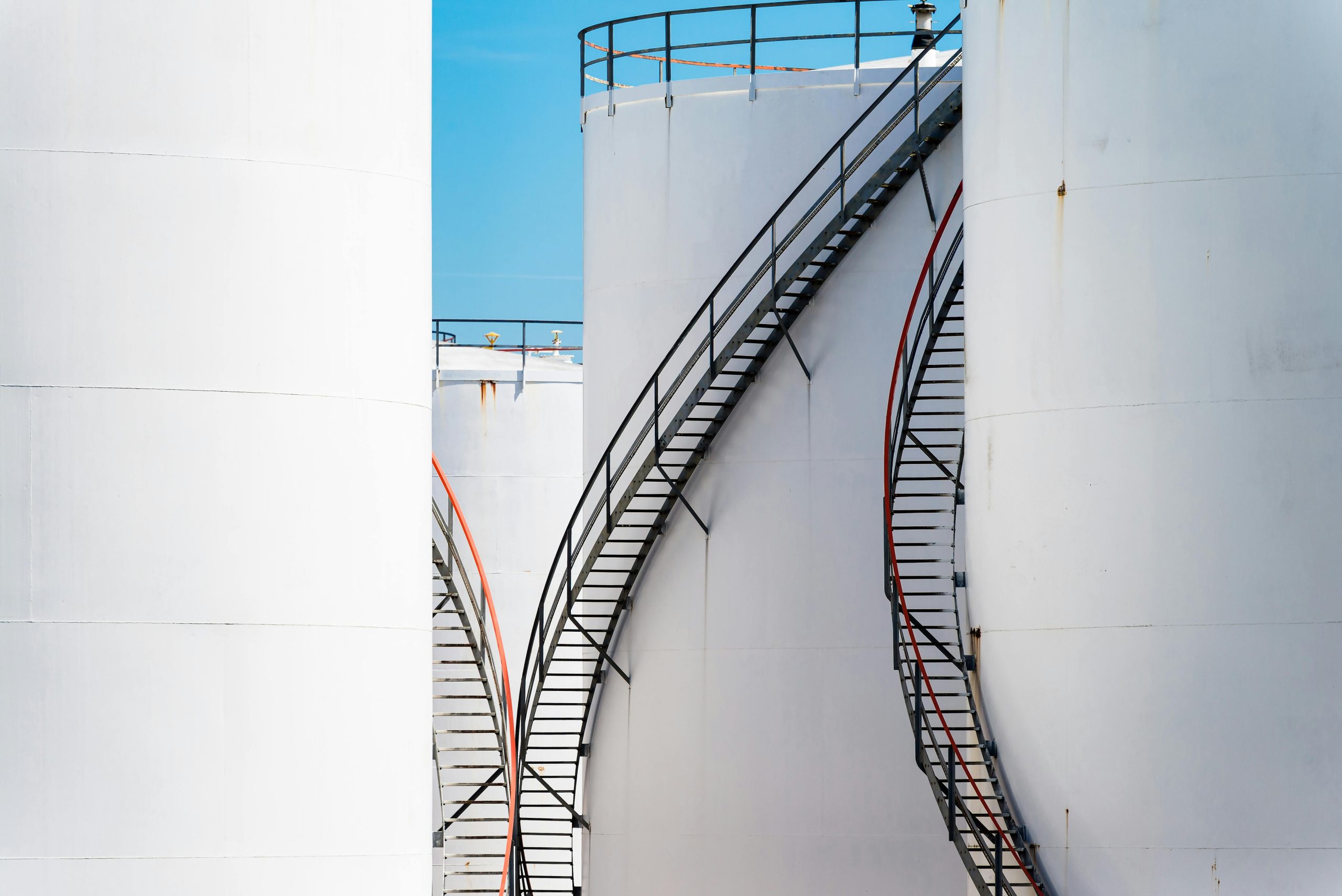

Re-Gen Robotics award winning robotic tank cleaning equipment is making tank cleaning and maintenance SAFER, FASTER & SMARTER, not only meeting but exceeding current health and safety standards by removing the risk to life which occurs during traditional hazardous cleaning methods.

Re-Gen Robotics tank cleaning service was the first of its kind operating in UK and Ireland. We primarily serve the oil and gas industry operating in refineries, storage terminals, pharmaceutical and chemical plants.

Our bespoke robotic equipment is self-contained, enters through manways of 24”/600mm dia. and is remotely operated from an air conditioned control room. Our robot takes the risk out of humans entering tanks in breathing apparatus to de-sludge the tanks manually.

Our robot using vacuum suction removes the sludge directly from where it is located within the tank. This technique works with any type and size of tank and any consistency of oil, even the most viscous oils contaminated with sand and scale. Mobilising sludge through the addition of heat and sometimes cutting agents.

This is why we are laser focused on cleaning tanks robotically, rather than manually.

How it works

Our Zone ‘O’ EX certified equipment is self-contained and arrives on site as one unit. Our Jet/Vac ADR tipping tanker is equipped with cranage to ensure a fast and effective site set up upon arrival. Equipment is set up in accordance with ATEX zoning regulations.

Robot enters the tank via ramps through a standard 600mm 24” / 600 manway. Our robot is operated from a fully airconditioned control room containing earthing points and Ex rated monitors to allow the operator to navigate and see inside the tank whilst cleaning is taking place.

Equipped with Ex certified cameras, our robot manoeuvres around internal tank furniture such as heating coils, pipework, roof legs, drains and sumps. Cleaning heads are selected, considering several factors at each works location based on material, phase or scope of works required.

Once the robot enters the tank, the sludge is treated and removed to our Jet/Vac tanker. As our robot never tires – we can operate on multiple shift patterns as agreed with client.

Manway as small as

24”/600mm

Tank diameter

20m +

Thorough cleaning

360°

Shell walls up to

2m high

Heavy and Light

Oils

Business Benefits

Safer

Our robotic technology sets new safety standards across in oil tank cleaning.

We have removed the need for confined space entries to de-sludge tanks, eliminating the risk of injury or death.

Faster

Cleaning time reduced by up to 70%.

3 operatives required, Site Supervisor, Robotic Operative, Jet/vac tank operator.

Less paperwork and permitting.

Reduces complex management procedures for site operator.

Smarter

All aspects of process managed from control room.

CCTV recorded footage available.

Financial

Outage time reduced.

No damage to assets.

No compromise of integrity from other cleaning methods.

Environmental

Reduction in water used during cleaning process.

Less risk of contamination due to human error.

Real time reporting of waste allowing site operator to track waste output.

Corporate Risk

By keeping employees and contractors safe on site helps achieve corporate ESG goals.

Isolating humans from significant hazards in tanks represents a step change in risk reduction for site operations.

Oil Refineries & Fuel Storage Terminals

Oil Refineries

We specialise in providing robotic tank cleaning services, primarily catering to the Oil and Gas industry, with our technology adept at handling the full range of viscous materials commonly found in such tanks.

Product Tanks

We specialise in providing robotic tank cleaning services, primarily catering to the Oil and Gas industry, with our technology adept at handling the full range of viscous materials commonly found in such tanks.

Crude Oil Tanks

We specialise in providing robotic tank cleaning services, primarily catering to the Oil and Gas industry, with our technology adept at handling the full range of viscous materials commonly found in such tanks.

Heavy Fuel Oil Tanks

We specialise in providing robotic tank cleaning services, primarily catering to the Oil and Gas industry, with our technology adept at handling the full range of viscous materials commonly found in such tanks.

Waste Oil Tanks

We specialise in providing robotic tank cleaning services, primarily catering to the Oil and Gas industry, with our technology adept at handling the full range of viscous materials commonly found in such tanks.

Frequently Asked Questions

Re-Gen Robotics is a service provider of tank cleaning to the oil and gas industries. We offer storage tank cleaning services which includes our bespoke equipment.

Yes, Re-Gen Robotics is a leader in the field of fully compliant, Ex Zone ‘O’ rated, ATEX storage tank cleaning robotic services.

Re-Gen Robotics can provide cleaning of tanks from 20m in diameter upwards. Our equipment is engineered such that there are no restrictions on hose length.

We require access to the tank bund for our robot and preferably our Jet/Vac tipping tanker and control room. However, we have operated in bund areas with out this. By using our self-contained Hiab crane we can lift our robot across bund walls.

Our robots fit through a standard 24”/600mm diameter manway via an extending ramp which is attached to the manway.

Yes, our robot is designed to be fully submerged in tank contents if necessary, the robot, CCTV and lighting system being waterproof.

Our robots are equipped with different heads to allow desludging, jetting and washing and can clean storage tanks with materials such as Heavy Fuel Oil, Crude Oil, sludge and even materials which have been heavily contaminated with dirt, debris, and scale.

Yes, our robots can clean tanks containing products such as Gasoline, Naphtha, Diesel, Heating oil and JET A1, amongst others.

Yes, our robot is equipped with ATEX approved, forward and rear facing cameras and lighting to allow the operator to navigate internal tank furniture safely. Using different robotic heads, we have many options to clean around these areas.

We have a variety of different tracks to manoeuvre on different types of tank floors. Through our continuous R&D process led by our inhouse team, we have developed tracks to suit both lined and unlined floors. All our tracks have been put through significant testing prior to ensure no damage occurs to client floors.

Yes, our robotic technology is equipped with ATEX approved forward and rear facing cameras and lighting to allow our operator to manoeuvre around obstacles such as roof legs.

Re-Gen Robotics can also clean the underside of floating roofs, foam dams/seals, roof drains and pontoons.

Operational hours of work are based on 12 hour shifts typically 7am – 7pm, including 90 mins total break time. A working shift pattern is agreed subject to client requirements.

With our self-contained kit including Jet/Vac tanker, cranage, control room and robot for easy transport, we currently operate throughout UK, Europe and USA.

Please complete our enquiry form following which one of our representatives will be happy to answer your questions on our tank cleaning services and provide you with a quotation.

Enquire Now

Our award winning robotic tank cleaning systems are ideal for forward-thinking, industry leading companies.